The client, a global gas and diesel firm, faced a critical challenge, i.e., the absence of a robust system to proactively monitor engine health. This lack of early warning detection and anomaly identification led to costly, unplanned downtime. To address this, the firm sought a comprehensive solution that would enable efficient management of large datasets, secure cloud-based data storage, real-time engine health monitoring, and actionable insights to optimize maintenance strategies.

AWS (Amazon Web Services)

Delta Lake

Matillion

Apache Spark

Databricks

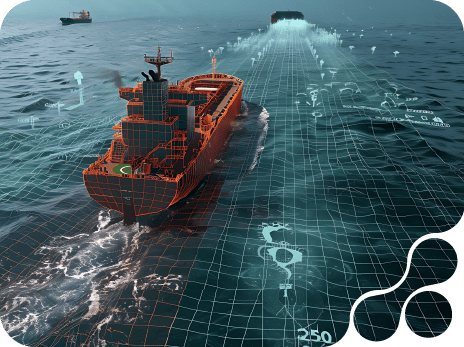

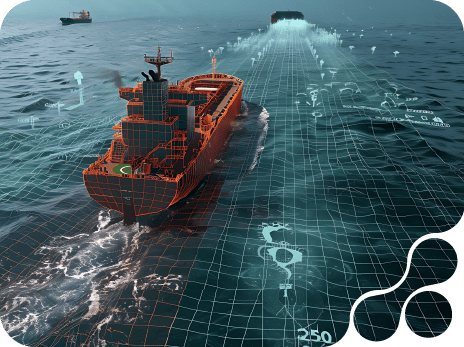

The oil and gas industry relies heavily on maritime transport to keep global supply chains running. However, shipping companies face mounting challenges in ensuring fleet reliability and efficiency amid market volatility and rising maintenance costs. Without proactive anomaly detection, undetected engine issues can lead to unexpected failures, costly repairs, and shipment delays—impacting supply chains across the world.

Amid similar challenges, a global gas and diesel engine firm faced the dilemma of ensuring optimal engine performance and minimizing unexpected downtime during product transportation. With over 120 ships transmitting 20+ signals daily, generating a massive volume of data, the company struggled due to the lack of a reliable system to proactively monitor engine health. Without an early warning system to detect anomalies and performance spikes, timely maintenance was compromised, leading to costly and disruptive breakdowns. As a result, they looked forward to establishing a robust platform for real-time KPI monitoring and alerting mechanisms on ship engines.

Leveraging our expertise in data analytics and machine learning, Bosch SDS partnered with the gas and diesel firm to develop a comprehensive solution for optimizing engine performance and reducing downtime. A team of dedicated data scientists and engineers implemented a cloud-based big data analytics platform.

This holistic solution included the following key initiatives:

We proposed a data-driven approach to revolutionize engine maintenance. Our solution enabled advanced anomaly detection and early warning systems for ship engines, helping the client address potential issues before they escalated. By facilitating continuous engine health monitoring, we ensured real-time identification of performance deviations, minimizing the risk of failures. Additionally, we developed a predictive model that accurately identified warranty cases linked to engine failures, enabling proactive maintenance. This not only optimized operational efficiency but also enhanced customer trust and positioned the client for long-term success in the maritime industry.

Advanced anomaly detection

Forecast-driven maintenance strategies

Minimized downtime

Real-time monitoring of engine performance

Optimized operational efficiency

Significant cost optimization

At Bosch SDS, we help industry leaders adopt an innovative approach combining advanced analytics and machine learning to harness data-driven insights. Bosch SDS’ proactive monitoring and maintenance platform enabled the client to drive enhanced operational efficiency and predictive maintenance. Through AI/ML-based pattern and correlation analysis, the client could easily identify anomalies and schedule timely maintenance processes. As a result, the client also witnessed significant cost reduction through minimized unexpected engine breakdowns and incidents. Moreover, the company also optimized resource utilization through efficient maintenance strategies and real-time insights reducing excessive spending on redundant maintenance checks. Improved OEE, equipment longevity, and reliable engine performance positioned the client as a dependable service provider, boosting customer confidence. Furthermore, the AWS-based cloud platform ensured scalability for managing growing data volumes and incorporating future innovations. Finally, the advanced digital platform positioned the client for long-term success in an increasingly data-centric maritime industry.