AI For Sustainable Manufacturing: Optimizing Energy Savings And ROI With Bosch SDS

Summary

Manufacturers are now focused not just on boosting ROI but meeting stringent sustainability standards without compromising product quality or production speed as well. The key to achieving this balance lies in AI—a technology that’s evolving at an unprecedented pace, continuously adapting to the demands of customers, markets, and industries. Now is the time to unlock AI’s full potential in harmonizing manufacturers’ mission-critical goals, and this blog is all about it.

Introduction

The manufacturing industry has undergone a dramatic transformation thanks to the power of AI, driving unprecedented levels of automation. From real-time machine behavior analysis and predictive maintenance that minimizes downtime to a seamlessly connected supply chain, AI-powered applications, and processes have revolutionized diverse functions – from procurement to production and distribution.

But the journey of AI’s impact doesn’t stop there!

As a heavily networked and operations-driven industry, manufacturing consumes vast amounts of energy and generates significant waste. The sector is projected to contribute 17% to the global carbon footprint between 2024 and 2050. It only makes sense for manufacturers to view sustainability as a critical strategic imperative rather than an option. They are now faced with the complex challenge of balancing stringent sustainability regulations, evolving product lifecycles, and growing consumer demands for eco-friendly practices—all while navigating supply chain disruptions, and rising costs, without sacrificing return on investment.

Here’s where AI emerges as a critical enabler of environmentally responsible manufacturing.

What role does AI play in a sustainable manufacturing environment?

Sustainable manufacturing isn’t confined to the factory floor; it’s a holistic commitment woven into every stage of the value chain, from raw material sourcing to production, quality control, and finally, logistics. These integrated practices are crucial for minimizing a company’s environmental footprint and demonstrating responsible global citizenship. One of these globally notable practices is producing an environmental, social, and governance (ESG) report, which many global manufacturers produce to track their sustainability efforts. This is a continuous process, encompassing limiting carbon emissions, adopting renewable energy sources, following sustainable waste management practices, and educating suppliers to promote positive environmental impacts in the supply chain. But while ESG reports reflect past efforts, they do not offer the foresight needed for proactive change or cost savings. Hence, AI steps in, providing real-time, data-driven insights and automation that enable companies to move beyond reactive reporting to proactive, ongoing optimization of sustainability throughout the entire value chain.

Companies can leverage AI – adopting an entire redesign of both hardware and software, which can empower them to reduce energy consumption, optimize waste reduction, streamline manufacturing processes, and ultimately, boost ROI. The foundation of AI-powered sustainable manufacturing rests on the convergence of real-time data streams: sensor data from connected machines and IoT devices, sophisticated algorithms that analyze and predict trends, enterprise data on inventory levels, and even external factors like weather patterns and market dynamics. Through this integrated intelligence leaders can unlock unprecedented opportunities for optimization across three key operational areas: raw material sourcing, factory floor operations (production, quality control, and waste management), and logistics.

3 stages to integrate AI for sustainable manufacturing

Procuring environmentally friendly raw materials for production using AI

Material waste poses a significant threat to our planet, contributing substantially to global warming. Given the diverse nature of products and raw materials used in manufacturing, the industry bears considerable responsibility for mitigating its environmental impact and embracing sustainable practices. AI offers powerful tools to minimize waste and energy consumption throughout the manufacturing lifecycle. By leveraging machine learning, predictive analytics, and optimization algorithms, AI-powered solutions can monitor, analyze, and precisely measure waste generation, enabling data-driven decision-making.

As raw material sourcing becomes more and more crucial by the day, AI can help identify & source alternative environmentally friendly raw materials. This is supported by AI-driven Life Cycle Assessment of Products (LCA) and creation of EPD reports (Environmental Product Declaration) which help in identifying the hotspots. This coupled with data mining techniques, enable manufacturers to evaluate material properties, carbon footprints, and recyclability, to identify eco-friendly alternatives. By integrating this data with production plans and supply chain optimization algorithms, they can streamline material delivery schedules and minimize disruptions, further reducing waste.

Furthermore, Advanced technologies such as Generative AI (Gen AI) and Natural Language Processing (NLP) empower manufacturers to analyze vast amounts of data from sustainability reports, supplier databases, and customer reviews. This intelligent analysis helps identify reliable, cost-effective, and sustainable materials, ensuring responsible sourcing practices. Predictive analytics plays a key role in assessing long-term material availability, evaluating supplier performance, and securing a stable, sustainable supply chain over time.

From downtime to uptime with AI-led manufacturing

Every factory presents a unique set of energy demands, creating distinct challenges for tracking, optimizing consumption, and conserving resources. AI empowers manufacturers to transform their shop floors into intelligent, future-ready facilities by addressing these specific challenges head-on:

- AI-Driven Product Recipe Simulator for efficient product development: The AI-powered product recipe simulator offers R&D and product development teams a powerful tool to virtually test and optimize product formulas. This innovative solution allows teams to experiment with eco-friendly raw materials while maintaining the product’s quality and performance. By simulating different recipes, companies can significantly reduce raw material waste and minimize the costs of prototype testing, avoiding the creation of products that don’t meet performance expectations. It’s a smarter, more sustainable approach to product development that saves both time and resources.

- Predictive maintenance to forecast faults: AI uses machine learning algorithms, predictive analytics, and computer vision to analyze images from IoT-connected devices and sensors to anticipate equipment failures. Organizations can leverage AI to analyze historical energy usage patterns from similar machinery and real-time data from currently connected equipment and predict potential breakdowns before they occur. This foresight allows for proactive maintenance, minimizing downtime, reducing energy waste, and optimizing operational costs.

- Smart Energy Management to save energy costs: Teams can leverage AI-powered Energy Management Systems (EMS) to analyze real-time data to identify patterns in both energy consumption and machine performance. By detecting anomalies in equipment behavior, AI-EMS can predict potential failures, enabling proactive intervention and preventing energy-intensive breakdowns such as equipment failures or malfunctions. Moreover, such systems integrate hardware, software, and intelligent controls to optimize energy usage, dynamically adjusting consumption based on demand and avoiding peak times, resulting in significant cost and energy savings.

- Automated Quality Control: Quality control is paramount in manufacturing. AI streamlines this process through computer-aided vision, utilizing image recognition and processing, along with data from heat/cold wave sensors and other connected devices. AI models trained on images of acceptable and defective products can accurately predict whether a unit requires rework, scrapping, or recycling. Furthermore, AI can analyze production data, incident reports, and customer feedback to identify areas for continuous improvement. This process helps improve KPIs like First Time Right (FTR) and First Pass Yield (FPY) which reduces wastage of raw materials, energy consumption and save on expenses.

- Intelligent Waste Management: AI plays a crucial role in enabling firms to minimize hazardous waste and optimize disposal methods. Computer-vision-enabled robots can sort waste materials based on hazard level and type, while Gen AI analyzes optimal disposal pathways to minimize environmental contamination. These AI-driven waste management systems significantly reduce waste generation, contributing directly to sustainability goals. By predicting the lifecycle and environmental impact of single-use products, AI can help personnel to source or develop more sustainable alternatives for in-demand goods.

Adopting new AI-driven sustainability solutions in logistics

The manufacturing industry’s transportation and logistics operations contribute significantly to human-induced carbon dioxide emissions. Integrating AI in manufacturing is the solution – enabling the creation of highly efficient distribution strategies and logistics plans that minimize energy consumption across the entire process, from fuel for deliveries to electricity for warehouses. Companies can utilize AI to intelligently account for a multitude of constraints, including cost, service levels, routing challenges, weather conditions, and environmental factors. Furthermore, AI can develop robust contingency plans to mitigate disruptions such as traffic congestion or severe weather, optimizing fleet management and ensuring resilience.

- Warehouse management: Teams can clearly define controls based on factors like demand frequency, item size, and storage capacities to design optimal warehouse layouts. Through this intelligent design, firms can streamline delivery sorting, reduce order swapping errors, and minimize the energy wasted on correcting mis-deliveries – including fuel consumption for returns, route replanning, and reassignments. AI-driven warehouse operations translate directly into cost savings by preventing product misplacement, damage, and other inefficiencies.

- Fleet management: With AI-based fleet management applications personnel can analyze real-time data on traffic, weather, vehicle specifications, delivery locations, and fuel costs to determine the most efficient transportation routes. By dynamically planning delivery paths that minimize travel time and fuel usage, teams can utilize AI to meet sustainability goals. Furthermore, AI applications provide clear, textual explanations for route selections, empowering logistics managers with actionable insights for data-driven decision-making that balances cost efficiency and environmental responsibility.

Ultimately, these efficiencies not only enhance operational performance but also contribute to sustainability by minimizing fuel consumption and waste, leading to a reduced carbon footprint.

Bosch SDS: Your technology partner for AI-led manufacturing

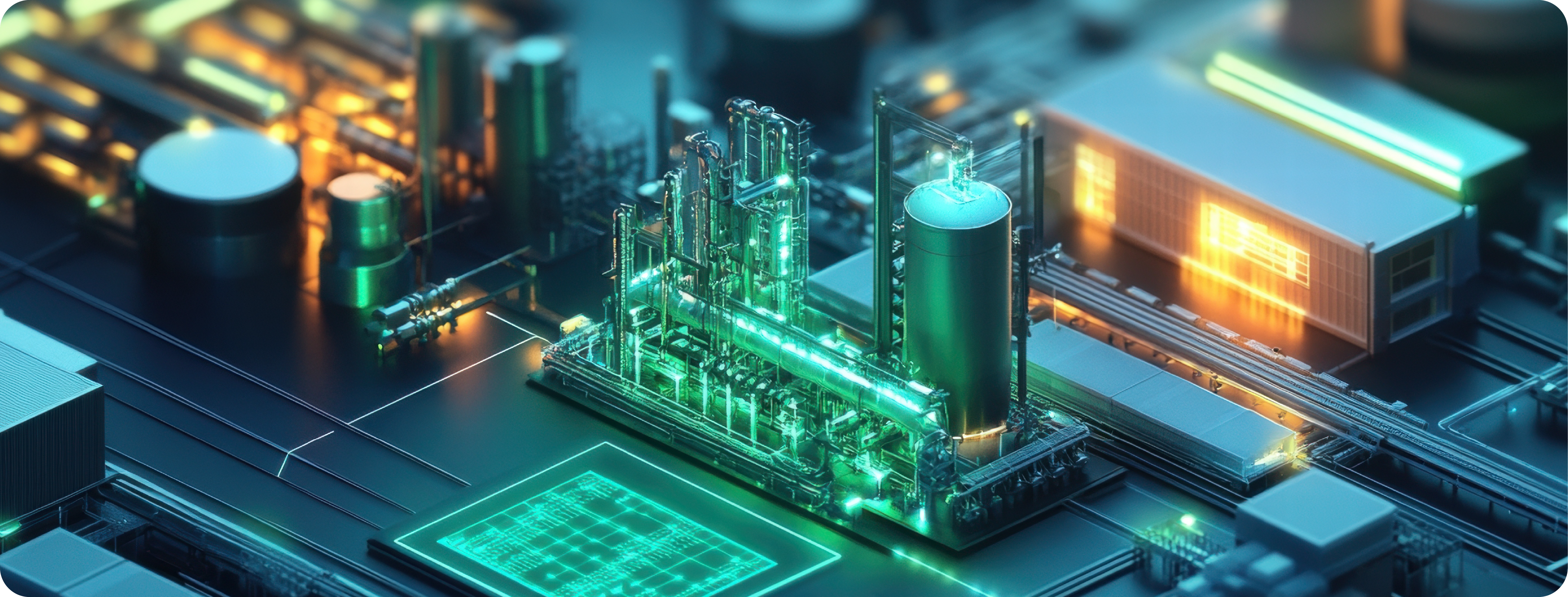

At Bosch SDS, our decades of deep expertise in smart sustainability solutions is the strength behind delivering tailored energy and utility management to elevate the manufacturing sector. Our focus ranges from pioneering energy management to optimizing climate control systems and modernizing utility infrastructure with advanced monitoring, data analytics, product development and automation to align with the industry’s evolving sustainability needs, including carbon neutrality. Central to our sustainability solution is DEEPSIGHTS – a cloud-based, customizable platform that integrates real-time data, advanced analytics, and edge-AI automation to enhance productivity, reduce energy consumption, and lower carbon footprints. This is also augmented by our full spectrum of expanded sustainable solutions, including smart utility management, innovative energy sourcing, and system upgrades that improve asset performance. Additionally, we also offer LCA studies and EPD report creation powered by RPA and AI. With our pre-built templates, we automate data preparation across functions like production, maintenance, logistics, and EoL, while allowing customization to fit the clients’ product and data needs.

With numerous satisfied clients across industries and the world, SDS’ holistic approach empowers manufacturers to balance sustainability with operational efficiency, achieve rapid returns on investment, and ensure robust ESG compliance. Through our commitment to sustainability, we support the manufacturing industry’s transition toward a greener, more efficient future.

<Read on> to know how Bosch SDS enabled a leading automotive manufacturer to embrace sustainability with a hybrid ASU system.